Bangladesh’s Garment Industry Rebounds: A Better Place To Work, A More Conscious Industry

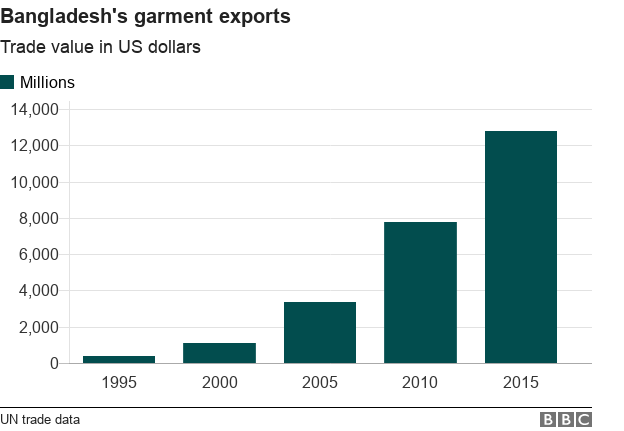

Bangladesh’s garment industry has raised its annual revenue from $19 billion to $34 billion in the last seven years, a 79 percent rise. This makes the country the world’s second-largest clothing exporter, with the sector accounting for 80 percent of the overall export earnings of Bangladesh.

The garment industry has experienced an impressive rebound in the last years, especially after 2012 and 2013’s disasters in two factories that left more than 1,200 workers dead. How has the industry recovered from tragedies like that?

According to expert Nazila Fathi: “Better labor regulations and safety conditions implemented after the workers’ deaths have played an important role. With these improvements in place, Bangladesh has become an attractive option for international clothing brands—especially those looking to diversify manufacturing locations and, more recently, those concerned about how global trade negotiations might affect their bottom line.”

Thanks to these regulations and a more involved role of the Bangladesh government in the garment industry, “Big brands are now actively looking for suppliers in Bangladesh,” added Sharif Zahir, executive director of Ananta Apparels and a board member of the Bangladesh Garment Manufacturers and Exporters Association.

Bangladesh’s garment exports

First things first: protect workers to protect the economy

Working conditions in the Bangladesh garment industry came under great scrutiny in 2012 after 117 people were killed at a fire at Tazreen Fashions, a garment factory near the capital city of Dhaka, and even more so five months later, when more than 1,100 workers lost their lives in the collapse of Rana Plaza, home to several garment factories. Global retailers, foreign governments, and international organizations then took steps to help the industry improve safety and labor conditions to prevent such tragedies in the future.

The Bangladeshi government also wanted to protect a central pillar of the country’s economy: the garment industry, which employs 4.4 million people, mostly women, and an industry that contributes more than 11 percent to the country’s GDP.

There have been significant improvements to factory safety since the internationally-backed schemes began sending teams of experts – both local and international – to address fire, electrical and structural concerns. This past June the International Labor Organization reported that 1,690 factories were complying with fire and building safety standards, and 655 factories were complying with worker safety standards. The demand for training programs also has increased. “We got so many inquiries that we had to add capacity and diversify our business,” said Zahir.

Authorities also worked to enforce the stricter safety codes and labor laws. While mostly larger factories operating in compliance with regulations have thrived, some smaller and mid-sized businesses that were unable to adopt the new standards suffered the consequences: Authorities have shut down 59 manufacturing units so far this year for failing to comply with new regulations.

IFC Country Manager Wendy Werner said such enforcement has led factories to take safety codes and environmental compliance more seriously—and the increased safety measures are a big reason “why big brands are increasing their presence in Bangladesh.”

In fact, at the end of 2018, the Alliance for Bangladesh Worker Safety released its fifth and final annual report announcing near completion of factory safety improvements as well the full execution of its renowned fire safety training and 24-hour worker helpline to the more than 1.5 million workers in Alliance-affiliated factories. “In these past five years, the Alliance, our member brands and the owners of Alliance-affiliated factories have achieved unprecedented progress toward the goal of improving safety in Bangladesh’s ready-made garment industry, while simultaneously helping to solidify Bangladesh’s standing as a global leader in garment exports,” said Alliance Executive Director Amb. Jim Moriarty. “Maintaining this progress must remain an ongoing effort—and for our member brands, it will remain a top priority long beyond the Alliance’s departure.”

“The US Embassy in Dhaka applauds the achievements of the Alliance, and will continue to strongly support the brands’ efforts to monitor safety and empower workers in their factories,” said U.S. Ambassador to Bangladesh Earl R. Miller. “With this work, the Alliance has set a standard for the industry to follow in Bangladesh.”

Highlights from the Alliance’s final report include:

· 93 percent of remediation across Alliance-affiliated factories is complete—including 90 percent of items most critical to life safety;

· 428 factories have completed all material items in their initial Corrective Action Plans (CAPs);

· Nearly 1.6 million workers have been trained to protect themselves in case of a fire emergency, and the Alliance has developed local training partners to expand the training beyond Alliance-affiliated factories;

· 28,000 security guards have been trained in fire safety and emergency evacuation procedures;

· More than 1.3 million workers across 941 Alliance and non-Alliance factories have access to Amader Kotha, the Alliance’s confidential worker Helpline;

· More than 1.5 million workers now have access to a 24-hour confidential worker helpline, which has been transferred to local management under Phulki and will soon be available to RMG factories throughout Bangladesh; and,

· 181 worker safety committees have been formed, giving workers a seat at the table with management in resolving safety issues within their factories.

Read more about the Bangladesh’s garment industry in our in-depth article Present And Future Of The Garment And Textile Industry In Bangladesh

Improved Environmental Practices

In addition to better working conditions, new initiatives in some Bangladeshi garment factories support improved environmental practices. IFC launched one of these programs—Partnership for Cleaner Textile, or PaCT—in 2013. It aims to increase the competitiveness of the Bangladeshi garment sector by working with international buyers and local apparel associations to help suppliers reduce the use of resources such as water and energy. By improving operational efficiency and resource consumption, local suppliers are able to meet standards required by global brands. Many large manufacturers, such as Sharif Zahir’s Ananta Apparels, have boosted their businesses through the program.

The PaCT program also works with financial institutions to help factories access finance. It has established a $200 million Green Transformation Fund, through which the Bangladeshi government supports low-cost financing for the textile industry to purchase new technologies for resource-efficiency upgrades.

Hernaldo Turrillo is a writer and author specialised in innovation, AI, DLT, SMEs, trading, investing and new trends in technology and business. He has been working for ztudium group since 2017. He is the editor of openbusinesscouncil.org, tradersdna.com, hedgethink.com, and writes regularly for intelligenthq.com, socialmediacouncil.eu. Hernaldo was born in Spain and finally settled in London, United Kingdom, after a few years of personal growth. Hernaldo finished his Journalism bachelor degree in the University of Seville, Spain, and began working as reporter in the newspaper, Europa Sur, writing about Politics and Society. He also worked as community manager and marketing advisor in Los Barrios, Spain. Innovation, technology, politics and economy are his main interests, with special focus on new trends and ethical projects. He enjoys finding himself getting lost in words, explaining what he understands from the world and helping others. Besides a journalist, he is also a thinker and proactive in digital transformation strategies. Knowledge and ideas have no limits.